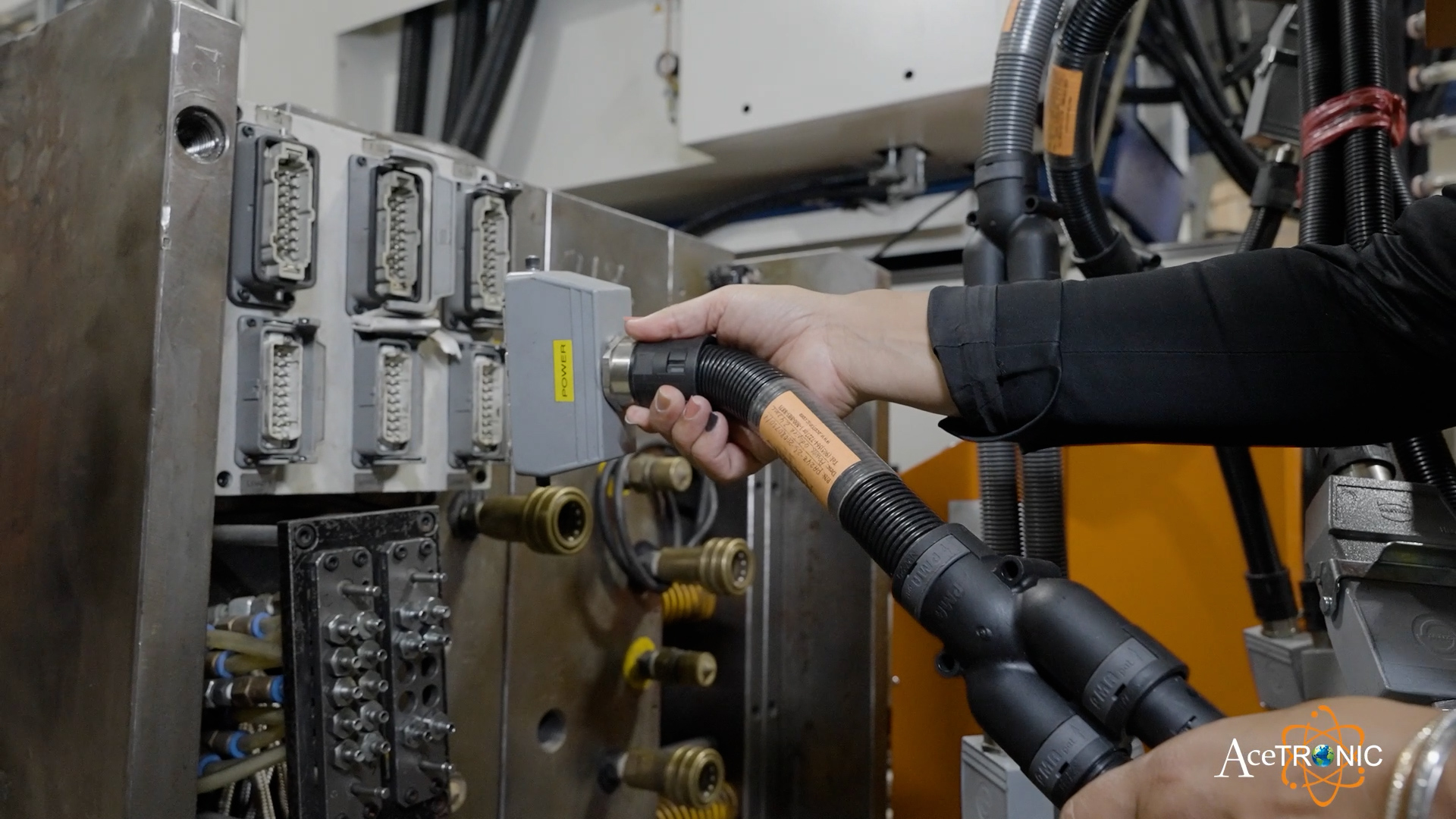

KEEP YOUR PRODUCTION RUNNING

Quality Mold & Thermocouple cables are essential to production.

Our team of cable specialists are committed to crafting superior cables, with high top-notch components that are engineered for longevity. We consistently provide high-quality solutions tailored to meet our customers' needs.

- Injection Mold Cables

- Thermocouple Cables

- Power/Thermo Combo

Talk to a hot runner cable expert.

Reach out to our team with your toughest cabling issues.

THE CABLE EXPERTS

We solve tough cabling problems

When it comes to cables, we're able to diagnose and propose solutions to your toughest cabling issues.

-

Fast and reliable cabling service. We build hot runner cables everyday; and we're fast.

-

Knowledgeable experts in custom cable design. We design and build cables to overcome your unique process challenges.

THE CABLE EXPERTS

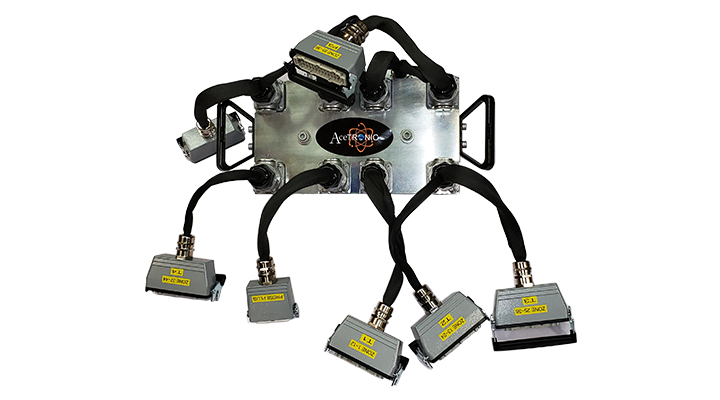

We design and build quality cable assemblies

Built with highest quality components to stand up to heavy production environments.

-

Quality components by respected manufacturers Harting, LAPP (EPIC), Staubli, and Hasco

-

Built in-house We build every cable in our facility designed just for hot runner cables.

TRUST THE EXPERTS

6 reasons to choose AceTronic

12,000+ Happy Clients

Rave reviews from our valued customers

Hear from our satisfied customers about their experience with our cabling solutions.

I am actually very impressed with the way the cable was manufactured, how the individual wires were laid out inside of the casing. It tells me a lot about Acetronic manufacturing process and I have only one word to describe it – Impressive!

John P.

Production Manager

Over the past several years, I have had to send in multiple sets of cables that have been damaged in my production facility. AceTronic has been able to repair these and send them back to me looking brand new.

Tim A.

Production Manager

Acetronic has been a great partner in our business since 2008. The friendly, knowledgeable, and professional team at Acetronic continuously provides high quality service and products.

Cyrus J.

President

NEWS

Insights: Hot Runner Cables

CABLING INSIGHTS

Don't worry. We have answers.

Read some insights into hot runner cables.

CABLING INSIGHTS

Why High-Quality Materials Matter In Hot Runner Controller Cables

Precision and reliability are non-negotiable in manufacturing, particularly in critical components like hot runner controller cables. These cables play a vital role in maintaining temperature control, which is crucial for ensuring consistent quality and efficiency in the manufacturing process.

CABLING INSIGHTS

Minimizing Temperature Fluctuations

High-quality cables help minimize temperature fluctuations, ensuring that the mold stays within the desired temperature range throughout the injection molding cycle. This is particularly crucial for thermally sensitive materials.

HOT RUNNER CABLES LINE-UP

The Essentials. For all

your cabling needs.

1-5 part

10 zone junction cable

24 Zone Cable

Dual End

Swivel Flex Cable

Dual Y

Flex Cable

Single Y

Flex Cable

Staubli Custom

Plate Cable System

CUSTOMER STORY

Custom cable assembly

resolves space constraint issues.

Customer brings cabling dilmemma to our experts. The old cable had multiple wires extending from the back; causing space constraints and making change overs impossible. Our custom built solution features the Staubli plate with braided cords and short connectors.

FAQs

Common cabling issues

Are your cables suffering from any of these issues; if so, you need to call AceTronic - 905-564-7227

Pushed-back pins are especially problematic when troubleshooting open circuits or other alarms because they can be intermittently connected. This can be seen on a hot runner controller as an open heater or thermocouple, and even thermocouple reverse or shorts.

Pushed-back pins or inserts are a common problem that can result in an intermittent current or an open circuit.

You can easily check to see if they are seated correctly by pressing a multimeter lead into the socket. If the insert is unseated, it will easily slide back and out of the socket.

We recommend preventative maintenance. Increasing amp ratings for larger heater applications or upgrade to a more robust connector system.

Worn levers and latches allow a loose fit between cables and the adjoining hot runner controller or mold box. These loose connections cause intermittent currents and sometimes open circuits.

Grounding from the hot half to the mold box through the cables and the controller and then to the facility ground is critically important. Unfortunately, ground connections are often loose, filthy dirty or missing entirely.

EASY ONLINE ORDERS

Ready to order your custom cable?

Use our online cable configurator to order a custom cable.

- Easy to Use

- Order Online

- RFQ Generator